Formidable Tips About What Is A Flex Connector

Flexible Metal Conduit FMC Connector 3 Pack Philippines Ubuy

What in the World is a Flex Connector? Let's Untangle This Mystery!

1. Understanding the Basics of Flex Connectors

Okay, so you've heard the term "flex connector" floating around, maybe from a DIY-inclined friend or while browsing some electrical how-to guides. What exactly is it? Think of it as a flexible, protective conduit that shields electrical wiring. It's like the body armor for your wires, ensuring theyre safe from physical damage and the elements. These connectors are often made of metal or plastic, and their primary function is to allow movement and flexibility in electrical systems. Imagine trying to bend a rigid pipe around a tight corner — nearly impossible! Flex connectors solve this dilemma, providing a safe and adaptable solution for wiring in tricky spots.

Now, why cant we just leave wires hanging loose, you might ask? Good question! Exposed wires are a huge safety hazard. They can be easily damaged, leading to short circuits, electrical fires, and even shocks. A flex connector keeps the wires bundled neatly and protected from abrasion, moisture, and other potentially damaging factors. It's a small component with a big impact on safety and reliability.

Beyond just protection, flex connectors also make installation a lot easier. They offer a degree of flexibility that rigid conduit simply can't match, particularly when you're working in tight spaces or navigating complex routes. They save time, reduce the risk of damaging wires during installation, and generally make life easier for electricians and DIY enthusiasts alike. It's like having a helper holding the flashlight exactly where you need it.

Consider the application too! There are different types of flex connectors for different situations. Some are liquid-tight, perfect for outdoor applications or areas where moisture is a concern. Others are designed for specific types of wiring or equipment. Choosing the right flex connector for the job is crucial for ensuring a safe and reliable electrical system. It's not a one-size-fits-all kind of thing; you need to know your stuff!

SAMSUNG 78 PIN CONNECTOR MOTHERBOARD FPC LCD DISPLAY FLEX CABLE

Delving Deeper

2. Exploring the Variety of Flex Connectors

Alright, now that we know what a flex connector is, let's dive into the different kinds available. You've got your basic metallic flex conduit (often called FMC), liquid-tight flexible metallic conduit (LFMC), and nonmetallic flexible conduit (NMFC), each with its own strengths and weaknesses. Think of it like choosing the right tool from a toolbox — you wouldn't use a hammer to screw in a screw, right?

FMC is your standard, everyday flex connector. It's relatively inexpensive and easy to work with, making it a popular choice for indoor applications where moisture isn't a major concern. LFMC, on the other hand, is the heavy-duty, waterproof version. Its designed to withstand harsh environments and protect wiring from water, oil, and other liquids. This makes it ideal for outdoor use, or in industrial settings where spills are common. NMFC is typically made of plastic and offers good flexibility and resistance to corrosion. It's often used in residential applications where flexibility and ease of installation are key.

Beyond these basic types, there are also specialized flex connectors designed for specific applications. For example, there are connectors with integrated grounding features, connectors designed for high-temperature environments, and connectors that are specifically approved for use with hazardous materials. The key is to understand the requirements of your specific application and choose the connector that best meets those needs. Don't just grab the first one you see!

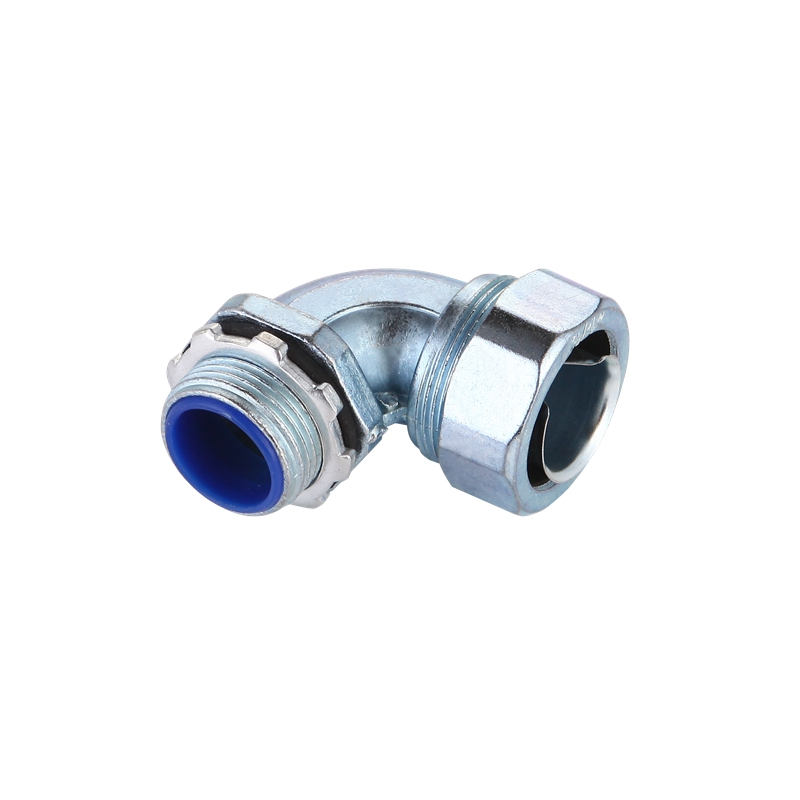

The connectors themselves also come in various sizes and configurations. They can be straight, 45-degree, or 90-degree angles, and they're available in a range of diameters to accommodate different wire sizes. Choosing the right size and configuration is crucial for ensuring a proper fit and a secure connection. It's like making sure you have the right size shoe — too big or too small, and you're going to have a bad time.

HighQuality Flex Connectors ChangYuan Co.

Why Should You Care About Flex Connectors? (Beyond Just Safety!)

3. Understanding the Importance of Flex Connectors

Okay, so we've established that flex connectors are important for safety, but there's more to it than just avoiding shocks and fires. These little gadgets also contribute to the overall efficiency and longevity of your electrical system. Think of them as an investment in the future of your wiring.

A well-protected electrical system is less likely to experience problems, which means fewer costly repairs and downtime. By preventing damage to wires, flex connectors help to maintain a stable and reliable electrical supply. This is particularly important in critical applications, such as hospitals, data centers, and manufacturing facilities, where even a brief power outage can have serious consequences. Imagine the chaos if the internet went down because a rat chewed through a cable!

Furthermore, using flex connectors can improve the aesthetic appearance of your wiring. Instead of having a jumbled mess of wires hanging everywhere, you can neatly route them through flex conduit for a clean and professional look. This is especially important in commercial settings, where appearances matter. Nobody wants to walk into a store and see wires dangling from the ceiling, right?

Also, when it comes time for inspections, properly installed flex connectors make things much easier. Inspectors can quickly verify that the wiring is properly protected and that the electrical system meets safety standards. This can save you time and money on inspection fees, and it can help to avoid costly code violations. Think of it as making life easier for everyone involved — including yourself!

Stainless Steel Flexible Connectors Dutypoint

Flex Connector Installation

4. Simple Steps for Installing Flex Connectors

While I always recommend consulting a qualified electrician for any electrical work, heres a general overview of how to install a flex connector. First, turn off the power! Seriously, don't skip this step. Electricity is not something to mess around with. Its like trying to pet a lion — it might go okay, but the odds are not in your favor.

Next, cut the flex conduit to the desired length using a suitable cutting tool. Make sure the cut is clean and free of burrs, which can damage the wires. Then, carefully insert the wires into the conduit. Its usually easier to pull the wires through if you use a wire lubricant, it's like adding butter to a sliding board. You may want to label the wires before you do this, or at least take a photo so you know where they go.

Once the wires are inside the conduit, attach the connector to the end of the conduit. There are various types of connectors, so follow the manufacturer's instructions carefully. Typically, you'll need to tighten a set screw or compression fitting to secure the connector to the conduit. Ensure the connection is tight and secure to prevent the conduit from slipping off. Loose connectors are like loose teeth annoying and potentially problematic.

Finally, connect the other end of the connector to the electrical box or equipment. Again, follow the manufacturer's instructions and make sure the connection is tight and secure. Once everything is connected, double-check your work to ensure that all connections are properly made and that the wiring is properly protected. Only then should you turn the power back on. And if you're not comfortable with any of these steps, please, please call a professional. Your safety (and your house!) is worth it.

STEEL INSULATED FLEX CONNECTOR 3/4IN. Rnv

Flex Connectors

5. Troubleshooting Flex Connector Issues

Even with careful installation, problems can sometimes arise with flex connectors. One common issue is corrosion, particularly in damp or corrosive environments. To prevent this, use liquid-tight connectors and ensure all connections are properly sealed. It's like wearing a raincoat when it's raining — it helps keep things dry and protected.

Another problem is physical damage to the conduit, such as dents or cracks. This can compromise the protection of the wiring and create a safety hazard. To avoid this, choose a conduit that is appropriately rated for the application and protect it from physical impact. You also want to make sure it's not near heat sources. If the conduit is too close to a heat source, it can melt. Consider it similar to what happens to ice cream on a hot summer day.

Sometimes, the connector itself can loosen over time, especially if it's subjected to vibration or movement. To prevent this, use locking connectors and periodically inspect the connections to ensure they're still tight. It's a little like checking the oil in your car — it's a simple task that can prevent a lot of trouble down the road.

Finally, make sure you're using the correct type of connector for the application. Using the wrong connector can lead to all sorts of problems, from water damage to electrical shorts. If you're not sure which connector to use, consult a qualified electrician or refer to the National Electrical Code (NEC). It's better to be safe than sorry, especially when it comes to electricity. It's like using the right ingredient to bake a cake!

FAQ About Flex Connectors

6. Frequently Asked Questions

Q: Can I use a flex connector outdoors?

A: Absolutely, but you'll need a liquid-tight flex connector (LFMC). These are specifically designed to withstand moisture and harsh weather conditions. Standard FMC isn't waterproof and can corrode quickly outdoors.

Q: How do I choose the right size flex connector?

A: The size of the connector depends on the number and gauge of the wires you're running through it. Consult the manufacturer's specifications or the National Electrical Code (NEC) for guidance. It's always better to err on the side of slightly larger, rather than trying to cram too many wires into a too-small connector.

Q: Is it safe to install flex connectors myself?

A: If you have a solid understanding of electrical principles and are comfortable working with wiring, you might be able to. However, electrical work can be dangerous, so if you're at all unsure, it's best to call a qualified electrician. Your safety is the most important thing!